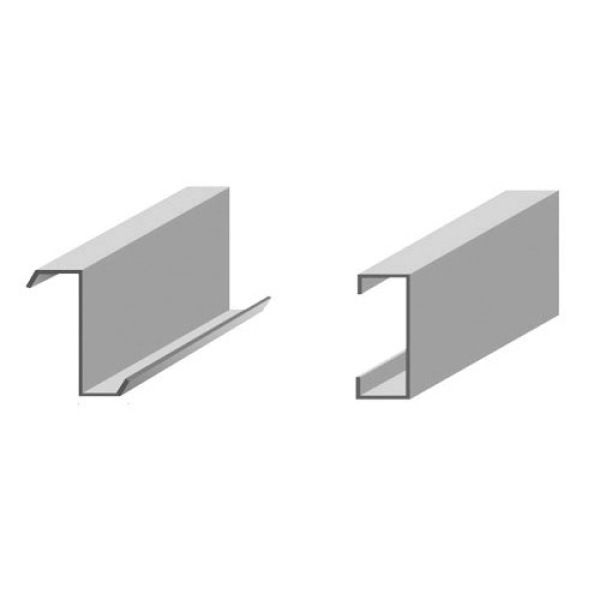

Z and C Purlins

Z and C Purlins

Z & C Purlins are made up with a help of quality-oriented cold-formed or rolled sheets mainly for a purpose of supporting the roof. The flexible shape of the (Z & C Purlins) is available in numerous forms and designs. Moreover, these purlins are extensively consumed in a plenty of the roofing solutions which mainly constitutes godowns, workshops, industrials sheds and much more. The interesting factor of such Z & C Purlins is that it can easily save up to 50% on the structural sheet in compliance with the hot rolled angles. We are the best service providers who render the crisp and clean purlins in design which do not allow the scope of any form of inaccurate lengths

We manufacture a broader assortment of Z & C Purlins and grills which are meant different for different forms of the application. These are manufactured with different forms of the quality oriented ingredients and raw material which are also supplied plain or punched.

At MAK Prefab Steel Contracting LLC, based in Dubai with fabrication in Umm Al Quwain, we supply precision-engineered Z and C purlins—critical components in prefabricated metal buildings. These roll-formed, high-tensile steel profiles are integral to supporting roofing and wall cladding, ensuring structural integrity across industrial, commercial, and institutional constructions.

Specification:

• Strong

• Reliable

• High-quality purlin

• Perfect girt steel framing system

However, such Z & C Purlins are broadly used in a large or say bulk quantity to the below-listed places:

• Building

• Garages

• Verandahs

• Carports

And in fact, at different forms of the places where strong, reliable steel framing seems to be a mandatory necessity. In addition to this, these Z & C Purlins are manufactured especially from the top-notch quality oriented galvanized steel especially in a fully integrated system meant to an allowing for the flexible design options. Alongside this, our services of the Z & C Purlins are manufactured from the high tensile steel which is considered as the most mandatory equipment especially when it comes to the following:

• Increased strength

• Reduced weight

• and a long serviceable life

All such services are meant to deliver the product on the long term

What Are Z‑Purlins and C‑Purlins?

Z‑Purlins are shaped with a wider and narrower flange, enabling efficient lapping across supports to form continuous span rigidity. They deliver superior strength and span capabilities for wider roof systems

C‑Purlins feature equal flanges and a simple “C” shape. Ideal for single spans and small to medium buildings, they offer reliable support and ease of handling

Key Advantages of Z & C Purlins

- High Strength-to-Weight Ratio: Cold-formed steel delivers reduced material weight with strong load-bearing capacity, saving up to 40–50% in steel weight versus hot‑rolled alternatives

- Cost Savings & Efficiency: Lower transport, handling, and construction costs—up to 30–40% weight reduction and 20–30% overall savings compared to traditional purlins

- Precision & Quality: Manufactured via cold roll-forming with tight tolerances, delivering straight, square sections with uniform dimensions

- Rapid Installation: Pre-punched holes and standardized profiles eliminate manual field cutting or drilling, speeding up site assembly

- Flexibility for Design: Z purlins support longer spans and overlapped connections; C‑purlins suit simpler layouts and wall framing applications

Product Specifications at MAK

- Material: Galvanized high-tensile steel (ASTM A653 or equivalent), up to ASTM Grade D (450 MPa yield strength)

- Thickness Range: From 1.2 mm up to 3.5 mm, depending on load requirements and span

- Standard Sizes: Web depths ranging from Z120 to Z300, C120 to C300, with flange widths between 40–90 mm and lip sizes of ~15–20 mm

- Accessories: Pre-drilled bracket holes, sag rods, bolts, anchor plates, and clips ensure secure and compliant installation

Design & Installation Considerations

Z‑Purlin Overlap Advantage: Z‑purlins can be lapped across supports, offering load continuity and reducing need for multiple supports—ideal for wide-span roofing

Orientation and Bracing: Proper orientation (top flange pointing up the slope) and lateral bracing (like sag rods or diaphragm sheeting) are key to preventing buckling or rotation under load

Corrosion Protection: Galvanized or zinc-magnesium coatings (e.g. ZM310) protect against rust, especially in coastal or humid UAE environments

Why Partner with MAK Prefab Steel?

- Local Expertise in UAE Conditions: Designed and manufactured to handle Dubai’s harsh heat, humidity, and wind loads, using corrosion-resistant coatings and robust steel grades.

- High Precision Factory Production: All profiles cold-formed and punched in our Umm Al Quwain plant, ensuring accuracy, quality, and factory consistency.

- End-to-End Service: From engineering design and section selection to delivery and installation—fully supported by MAK’s turnkey approach.

- Cost & Time Savings: Lightweight and pre-fabricated components reduce logistic costs and onsite labor.